the first mechanical connection system for a line pipe of its kind

designed to be measurable, repeatable, and fully documented.

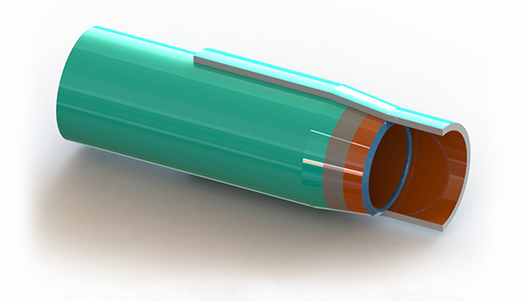

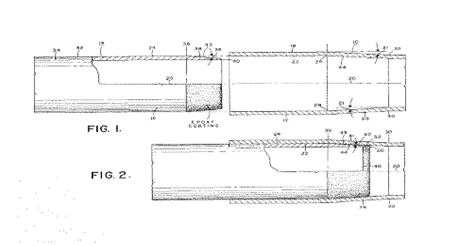

The joints of the mechanical connection system are formed without

welding, threaded pipe ends, or separate coupling devices.

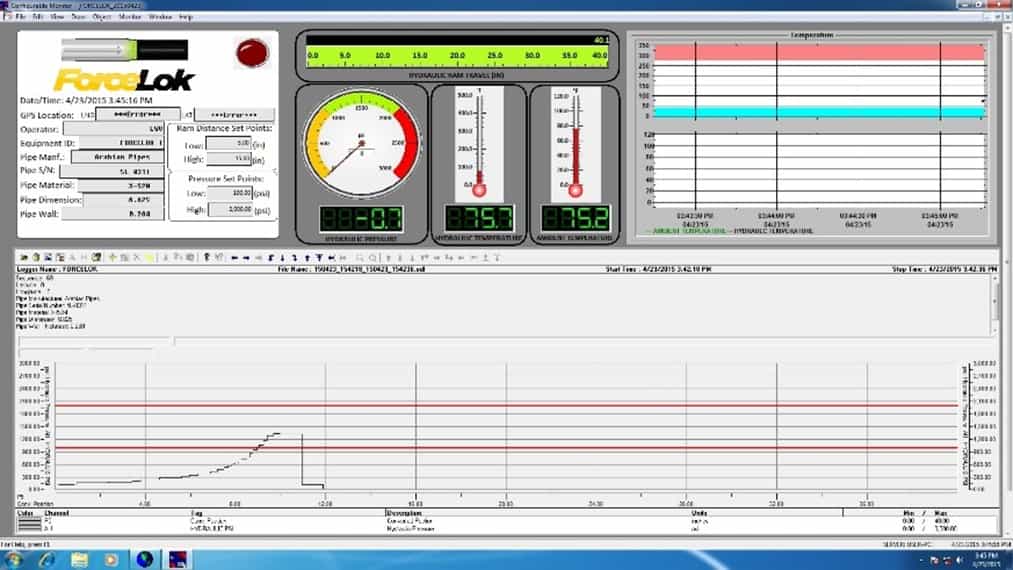

The SIX US Issued Patents and FOUR Foreign Patents Issued in

Tunisia, South Africa, India, and China; and the THREE ISOs based on

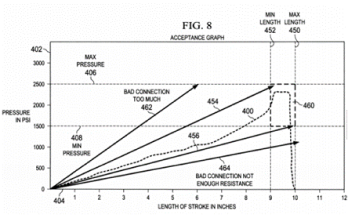

the Force-Lok Computerized Monitoring System were designed to ensure

Quality Control in the manufacturing of the End Preparations in the

mechanical pipe joining system and also provides monitoring and

documentation in the field during the joint Assembly Process of the

Force-Lok Mechanical Pipe Connection System.

Force-Lok has developed a revolutionary pipe joining system for the pipeline industry. The Patented Force-Lok Mechanical Pipe Joining System is a non-welded, connection that is compatible with the corrosion-resistant internally coated pipe. All Force-Lok connection systems were designed for numerous pipeline applications including pipelines transporting oil, gas, water, steam, corrosive liquids, and CO2 and are available for pipeline applications in sizes ranging from 2 inches to 24 inches. The Force-lok Computer Monitoring System monitors end-prep and field assembly operations in real-time and gathers important data for pipeline operators.

ForceLok Field Assembly unit produces approximately 10 to 15 joints/hour, or up to 1,800 meters per day

Pipeline Production Rate Comparison between ForceLok and Welding